In the realm of advanced engineering applications, the adoption of plastic bearings has been gaining significant momentum. As industries look for innovative solutions to enhance performance and reduce costs, plastic bearings offer unique advantages such as lightweight construction, resistance to corrosion, and low-friction properties. Industry expert Dr. Emily Carter, a renowned researcher in polymer materials, highlights the transformative potential of these components, stating, "Plastic bearings not only streamline the manufacturing process but also optimize the functionality of a wide array of machinery."

With the anticipated advancements leading up to 2025, understanding the trends in plastic bearings will be crucial for engineers and manufacturers aiming to leverage the benefits of these components effectively. The integration of materials science with engineering prowess is driving the evolution of plastic bearings, paving the way for smarter, more efficient designs. As we delve into the top trends shaping the future of this industry, it becomes evident that plastic bearings are poised to play a pivotal role in redefining performance standards across various sectors.

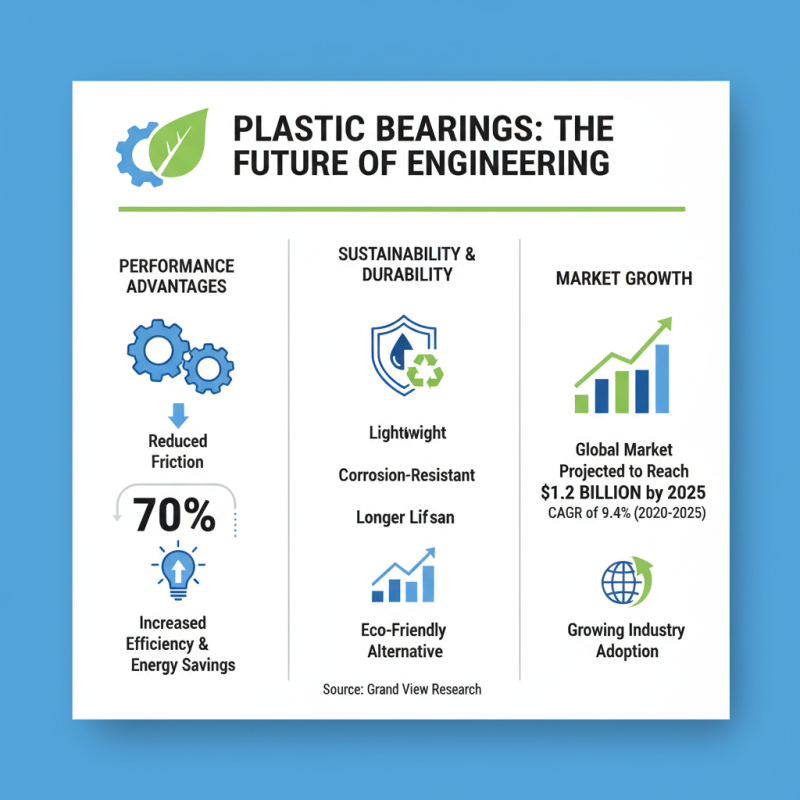

The emergence of plastic bearings in advanced engineering industries has been driven by their superior performance characteristics compared to traditional materials. Recent studies highlight that plastic bearings can reduce friction levels by up to 70% in certain applications, translating to increased efficiency and lower energy consumption. As industries increasingly prioritize sustainability, the use of lightweight and corrosion-resistant materials found in plastic bearings positions them favorably in the market. A report from Grand View Research indicates that the global plastic bearings market is projected to reach USD 1.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 9.4% from 2020, underscoring the growing acceptance of these innovative components in demanding applications.

Furthermore, the versatility of plastic bearings has contributed to their rise across various advanced engineering sectors, including aerospace, automotive, and robotics. Their ability to withstand extreme temperatures and harsh chemical exposures makes them ideal for applications previously dominated by metal components. According to a report by Mordor Intelligence, the aerospace segment is anticipated to see the highest adoption rate, fueled by developments in weight reduction initiatives and advancements in performance materials. The inherent advantages of plastic bearings—notably their maintenance-free operation and reduced noise levels—are revolutionizing component design, allowing engineers to explore new possibilities in mechanical systems without the limitations imposed by conventional materials.

The landscape of plastic bearings is rapidly evolving, driven by key materials and innovative technologies that enhance performance in advanced engineering applications. According to a report by the International Journal of Advanced Manufacturing Technology, the plastic bearings market is expected to expand at a compound annual growth rate (CAGR) of 7.5% through 2025, largely fueled by the increasing demand for lightweight and corrosion-resistant components in the automotive and aerospace sectors. This surge is largely attributed to advancements in polymer science, leading to the development of high-performance thermoplastics such as polyether ether ketone (PEEK) and polyamide (PA), which provide exceptional mechanical properties and reduce friction significantly.

Innovations in manufacturing techniques, such as 3D printing and injection molding, are also playing a crucial role in the evolution of plastic bearings. These methods allow for more complex geometries and customized solutions that traditional machining cannot achieve, leading to improved performance and application-specific designs. A study published in the Journal of Polymer Engineering highlighted that these advanced manufacturing processes can reduce material waste by up to 30%, while enhancing the structural integrity of the bearings. Furthermore, integration of smart technologies, like embedded sensors for real-time monitoring, is paving the way for next-generation plastic bearings that offer greater operational efficiencies in demanding environments. This combination of materials innovation and cutting-edge manufacturing is set to redefine the capabilities and applications of plastic bearings in the years to come.

Plastic bearings have gained traction in advanced engineering applications due to their remarkable performance advancements over traditional metal bearings. One of the defining features of plastic bearings is their lightweight nature, which not only reduces the overall system weight but also enhances energy efficiency. This is particularly crucial in industries like aerospace and automotive, where every gram can impact performance. Additionally, plastic bearings demonstrate excellent corrosion resistance, making them suitable for harsh environments where metal bearings would fail. Their ability to operate effectively without lubrication also reduces maintenance costs and increases reliability.

When comparing plastic bearings to their traditional counterparts, it becomes evident that plastic offers superior vibration dampening properties. This characteristic is essential in applications requiring precision and noise reduction. Furthermore, plastic bearings can often operate at a wider temperature range, ensuring optimal performance in challenging conditions. Engineers should consider these enhancements when selecting bearing types for their designs.

Tips: When choosing plastic bearings, always evaluate the specific application requirements, including load capacities and operating environments. It's advisable to perform thorough testing to ensure compatibility and performance longevity in engineering projects. Regularly review advancements in materials and technologies, as the field of plastic bearings is rapidly evolving, potentially offering even better alternatives for future applications.

Plastic bearings are rapidly becoming essential components in aerospace and automotive engineering due to their lightweight nature, resistance to corrosion, and superior performance in harsh environments. In aerospace applications, where weight savings are critical for fuel efficiency and performance, plastic bearings provide a reliable alternative to traditional metal bearings. They excel in applications such as actuators and landing gear components, where durability and weight reduction are paramount. Furthermore, these bearings can operate effectively at a wide range of temperatures, making them suitable for the extreme conditions often encountered in flight.

In the automotive sector, plastic bearings contribute to the development of more efficient and sustainable vehicles. With the growing trend towards electric and hybrid vehicles, manufacturers are increasingly adopting plastic bearings in various systems, such as electric motors, cooling systems, and suspension assemblies. These bearings not only help reduce vehicle weight but also lower friction, thereby enhancing overall energy efficiency. The ability of plastic bearings to withstand lubricants and environmental contaminants further ensures their long-term reliability in demanding automotive applications, paving the way for innovations in vehicle design and performance.

The drive toward sustainability is significantly reshaping the landscape of plastic bearing technologies, particularly as industries increasingly prioritize eco-friendly practices. According to a report by Grand View Research, the global plastic bearings market is projected to expand at a compound annual growth rate (CAGR) of 8.5% from 2021 to 2028, driven by a heightened focus on reducing the environmental impact of manufacturing processes. Innovations in biodegradable and recyclable materials are paving the way for a new generation of plastic bearings that not only meet performance standards but also contribute to a circular economy.

One notable trend is the adoption of environmentally friendly polymers, such as bio-based nylon and polylactic acid (PLA), which significantly reduce the carbon footprint associated with the production of traditional bearing materials. In fact, studies show that using bio-based polymers can reduce greenhouse gas emissions by up to 80% compared to conventional petroleum-based options. This shift not only meets regulatory pressures but also aligns with consumer demand for sustainable products.

Tips for engineers considering the transition to sustainable plastic bearings include conducting a lifecycle assessment to understand the environmental impact of different materials, collaborating with suppliers who prioritize sustainability in their manufacturing processes, and testing products under real-world conditions to ensure durability and performance. By prioritizing sustainable solutions, companies can not only comply with emerging regulations but also enhance their brand reputation in an increasingly eco-conscious market.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.