In the ever-evolving world of manufacturing and precision engineering, stainless steel balls stand out as pivotal components utilized across a multitude of applications. According to a recent market analysis by Smith & Associates, the global market for stainless steel balls is projected to grow at a CAGR of 5.2% over the next five years, reflecting an increasing demand driven by industries ranging from aerospace to automotive. These small yet robust spheres are valued for their durability, resistance to corrosion, and high load-bearing capacity, making them essential for various mechanisms, including bearings, valves, and even medical devices.

As stated by leading industry expert Dr. Emily Johnson, “The versatility of stainless steel balls is a testament to their crucial role in facilitating smooth and efficient operations in countless applications.” This enduring material not only enhances the reliability of machinery but also contributes to the overall efficiency of systems where they are employed. Understanding the best uses, benefits, and considerations when purchasing stainless steel balls is vital for professionals across numerous sectors. With this guide, we aim to provide comprehensive insights into selecting the right stainless steel balls tailored to specific needs while highlighting their inherent advantages.

Stainless steel balls come in various types and materials, each tailored for specific applications and environments. The most common varieties include Type 304 and Type 316 stainless steel balls, both of which derive their corrosion resistance from chromium and nickel content.

Type 304 is often used in general applications due to its excellent corrosion resistance and durability, while Type 316 offers better protection in more aggressive environments due to the addition of molybdenum, making it highly suitable for marine and chemical applications.

In addition to material types, the manufacturing process can also have a significant impact on the performance characteristics of stainless steel balls. For instance, balls that undergo precision grinding and polishing are often more suitable for high-speed machinery and equipment where low friction and reduced wear are critical. Furthermore, the choice of material can affect thermal and electrical conductivity, hardness, and overall longevity. By understanding these types and materials, users can select the appropriate stainless steel ball for their specific needs, ensuring optimal performance and reliability in their respective applications.

Stainless steel balls are essential components in various applications, offering numerous benefits due to their unique properties. One of the primary advantages of using stainless steel balls is their exceptional corrosion resistance, which allows them to maintain performance even in harsh environments. According to industry reports, stainless steel balls exhibit a corrosion resistance rate of up to 87%, making them ideal for use in industries such as automotive, aerospace, and food processing. Their ability to withstand extreme temperatures and pressures further enhances their suitability for demanding applications.

Furthermore, stainless steel balls are known for their durability and longevity. When properly maintained, these components can last significantly longer than their counterparts made from other materials. A study conducted by the American Society of Mechanical Engineers found that utilizing stainless steel balls can reduce replacement costs by up to 40% over time, presenting significant savings for manufacturers. Their high strength-to-weight ratio also contributes positively to the overall performance of machinery, reducing energy consumption and improving efficiency.

Tips: When selecting stainless steel balls for specific applications, consider the grade of stainless steel, as this can affect performance and durability. Additionally, ensure proper lubrication is used to minimize wear and enhance operational efficiency. Regular inspections can help identify any signs of wear early, ensuring optimal operation and extending the lifespan of the components.

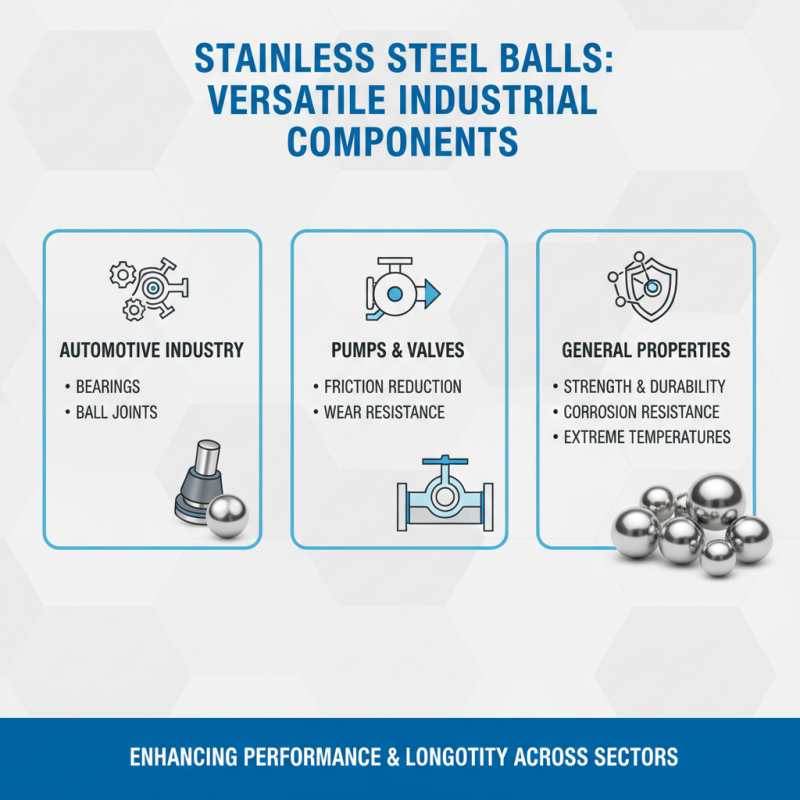

Stainless steel balls are versatile components widely used across various industries due to their strength, durability, and resistance to corrosion. One of the most prominent applications is in the automotive industry, where they are utilized in bearings and as ball joints. Their ability to withstand extreme temperatures and pressures makes them ideal for enhancing the performance and longevity of vehicle components. Additionally, stainless steel balls are critical in the manufacturing of pumps and valves, ensuring smooth operation by reducing friction and wear.

In the aerospace sector, stainless steel balls play a vital role in improving the reliability and efficiency of aircraft systems. They are utilized in actuators, landing gear, and control mechanisms, where precision and resilience are paramount. Beyond transportation, these balls are also crucial in the medical field, where they are employed in medical devices and surgical instruments. Their biocompatibility and ease of sterilization make them suitable for applications that require stringent hygiene standards. The diverse applications of stainless steel balls demonstrate their importance in enhancing performance and ensuring safety across multiple industries.

When considering the purchase of stainless steel balls, several essential factors should guide your decision-making process. First and foremost, the type of stainless steel used in the manufacturing process is critical as it determines the ball's corrosion resistance, strength, and overall durability. Common grades, such as 304 and 316 stainless steel, each offer varying levels of resistance to environmental factors, making it important to choose the right grade based on the intended application, whether it be in marine settings or underground environments.

Another crucial consideration is the size and diameter of the stainless steel balls. Various applications require specific sizes, and even slight deviations can impact performance. Additionally, the surface finish should not be overlooked; a polished finish can enhance aesthetic appeal and reduce friction in moving parts, while a rougher finish might be advantageous in certain industrial applications. Lastly, understanding the tolerances—how strict the ball's dimensions need to be—will ensure optimal performance and longevity in your selected use case. By carefully evaluating these factors, you can make informed decisions that align with your specific needs.

Maintaining stainless steel balls is crucial for ensuring their longevity and optimal performance in various applications. According to an industry report by the American Society of Mechanical Engineers, proper maintenance can extend the life of stainless steel components significantly, sometimes up to 50%. Regular cleaning is essential, as contaminants or corrosive substances can lead to surface rust or pitting. A simple solution of warm soapy water followed by thorough rinsing can effectively remove dirt and grime. For more rigorous cleaning, a mixture of vinegar and water can be applied, which helps in maintaining the shiny appearance without damaging the metal.

Furthermore, lubrication plays an essential role in the maintenance of stainless steel balls. Reports from the Society of Tribologists and Lubrication Engineers emphasize the importance of using appropriate lubricants, particularly in high-friction applications. This minimizes wear and tear and reduces the risk of failure. It's recommended to use food-grade lubricants in applications involving food or pharmaceuticals to ensure safety. Lastly, regular inspection can catch early signs of wear, allowing for timely replacement or servicing, which can significantly prevent costly downtimes and enhance the overall efficiency of operations using stainless steel balls.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.