In the realm of engineering and manufacturing, precision balls play a pivotal role in enhancing performance and ensuring reliability across various applications. According to a recent analysis by the Precision Ball Manufacturers Association, the global market for precision balls is projected to reach $2.5 billion by 2025, driven by increasing demand in sectors such as automotive, aerospace, and industrial machinery. This growth underscores the necessity of utilizing high-quality precision balls to meet the rigorous standards of modern projects.

Industry expert Dr. Emily Chen, a leading researcher in ball bearing technology, emphasizes the significance of selecting the right precision balls for optimal outcomes. She states, "The precision of balls directly influences the efficiency and longevity of mechanical systems. Investing in superior precision balls is not just a choice, but a necessity for achieving ultimate performance." As engineers and manufacturers seek to refine their projects, understanding the unique characteristics and benefits of various precision balls becomes essential.

This article presents a curated list of the top 10 precision balls that are critical for maximizing performance in your projects. By evaluating factors such as material composition, size precision, and application suitability, we aim to guide you towards making informed choices to enhance your operational success.

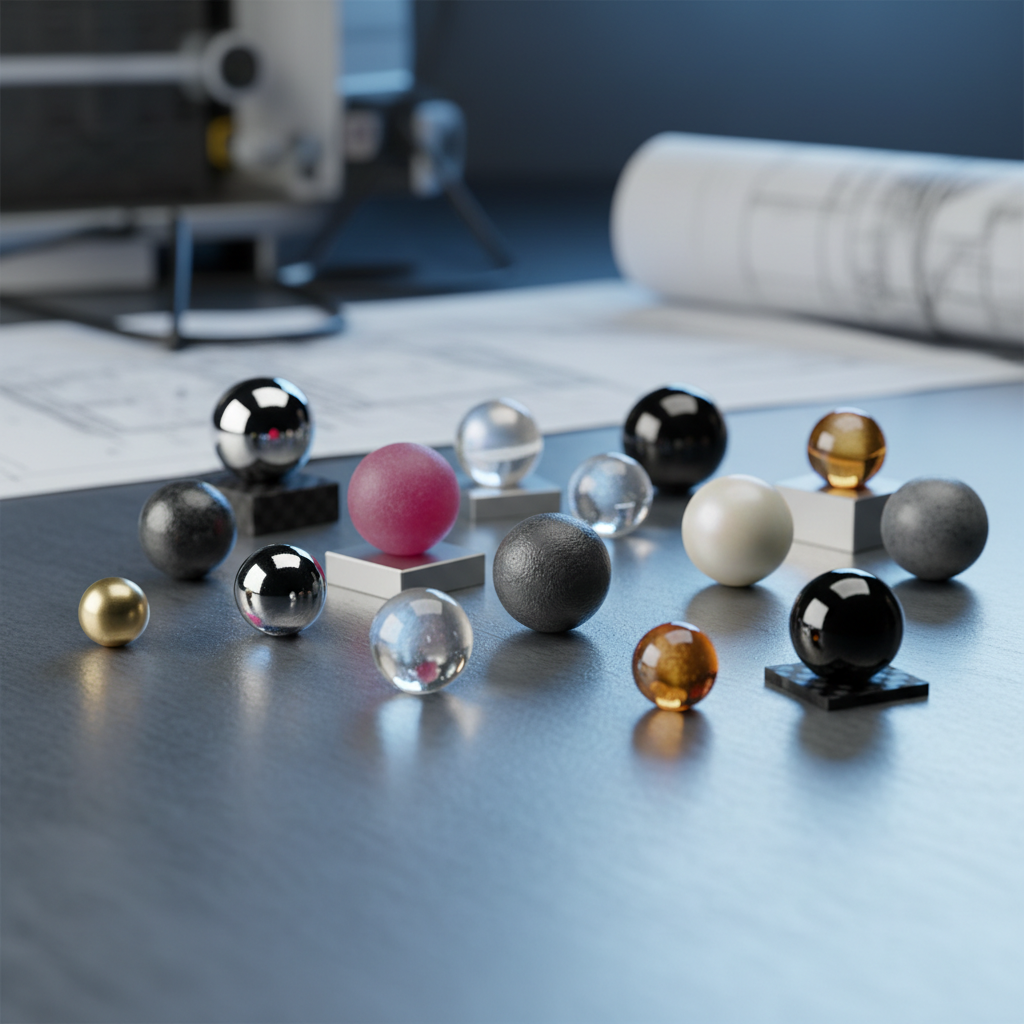

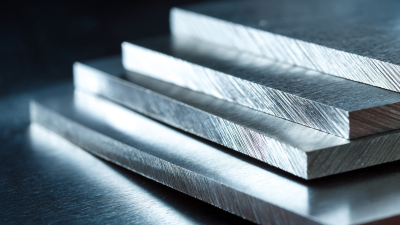

When selecting precision balls for optimal performance in your projects, several essential features should be at the forefront of your decision-making process. First and foremost, the material plays a crucial role in determining the durability and functionality of the balls. Common materials like stainless steel, ceramic, and plastic each offer distinct benefits; stainless steel is known for its strength and corrosion resistance, while ceramics excel in high-temperature applications. Understanding the specific requirements of your project will guide you in choosing the most suitable material.

Another key feature to consider is the tolerance level of the precision balls. Tolerance refers to the allowable deviation from the specified diameter, and higher precision is usually associated with lower tolerance levels. Choosing precision balls with tight tolerances ensures greater accuracy and consistency in your applications, minimizing the risk of component failures. Additionally, surface finish is an important factor, as smoother finishes can reduce friction and wear, enhancing the overall performance of your machinery or devices. By focusing on these essential features, you can ensure that the precision balls you select will meet the demands of your project effectively.

The material composition of precision balls significantly influences their performance and durability in various applications. High-quality materials such as stainless steel, ceramic, and plastic are commonly used in manufacturing precision balls. Stainless steel balls are particularly valued for their strength and corrosion resistance, making them ideal for environments that experience moisture or chemical exposure. In contrast, ceramic balls offer superior hardness and reduced friction, ensuring long-lasting performance in high-speed applications or where weight savings are critical.

Another essential factor to consider is the manufacturing process, which can affect the structural integrity of the materials used. For instance, precision balls made from heat-treated materials exhibit enhanced toughness and load capacity, increasing their reliability in demanding environments. Furthermore, the specific requirements of a project—such as load conditions, operating temperatures, and environmental factors—should guide the choice of material composition. By understanding how different materials contribute to performance and durability, engineers and project managers can select the optimal precision balls for their specific needs, ultimately facilitating the success of their projects.

When it comes to precision ball manufacturing, a few brands have notably set the standard for quality and innovation. Companies like SKF and Timken have built their reputations by investing in advanced technology and rigorous testing protocols. SKF, with its extensive history in bearing manufacturing, applies cutting-edge techniques to produce precision balls that offer superior performance in various applications, from automotive to aerospace. Their commitment to research and development ensures that their products consistently meet the evolving demands of the industry.

Another key player is Schaeffler, known for its precision engineering and a broad portfolio of precision balls and bearings. Schaeffler’s products are designed to provide optimal efficiency and reliability, making them a popular choice among manufacturers seeking to enhance their project outcomes. With a focus on sustainability and durability, Schaeffler leads the way in delivering precision balls that not only perform excellently but also comply with environmental standards. These top brands continue to drive the industry's progress, ensuring that customers have access to the highest quality precision balls for their projects.

Precision balls play a pivotal role in various industries, contributing to the efficiency and accuracy of numerous applications. In the automotive sector, for instance, precision balls are integral in ball bearings, which reduce friction and enhance the durability of moving parts. Their consistent size and shape allow for smoother operation of engines and transmissions, ultimately leading to improved fuel efficiency and vehicle performance.

In the aerospace industry, precision balls are used in critical components such as actuators and control surfaces, where exactness is paramount. The reliability of these tiny spheres ensures that aircraft achieve the desired thrust and maneuverability, safeguarding both performance and passenger safety. Similarly, in the medical field, precision balls are essential in devices like surgical instruments and diagnostic equipment, where precision is a matter of life and death. Their ability to maintain high stability under varied conditions sets the foundation for innovations that can significantly impact patient outcomes.

| Ball Type | Material | Diameter (mm) | Hardness (HRC) | Applications |

|---|---|---|---|---|

| Chrome Steel Ball | Chrome Steel | 3 | 58-62 | Bearings, aerospace |

| Stainless Steel Ball | Stainless Steel | 5 | 48-52 | Automotive, marine |

| Plastic Ball | Nylon | 10 | - | Food industry, medical devices |

| Ceramic Ball | Zirconium Oxide | 8 | - | High-speed bearings, medical applications |

| Carbon Steel Ball | Carbon Steel | 6 | 60-64 | Industrial machinery, automotive |

| Titanium Ball | Titanium | 3 | - | Aerospace, medical implants |

| Glass Ball | Glass | 4 | - | Decorative, precision instruments |

| Lead Ball | Lead | 5 | - | Counterweights, industrial applications |

| Rubber Ball | Rubber | 15 | - | Seals, cushioning applications |

| Aluminum Ball | Aluminum | 5 | - | Aerospace, automotive components |

Maintaining precision balls is crucial for ensuring their longevity and accuracy in any project. Regular cleaning is the first step to prevent dirt and debris build-up that can affect performance. Use a soft cloth and appropriate cleaning agents to gently wipe down the surfaces. Avoid abrasive materials that might scratch or damage the precision balls. Furthermore, maintaining a controlled environment with stable temperature and humidity levels can help prevent corrosion and degradation over time.

Another essential maintenance tip is to perform routine inspections for signs of wear or damage. Look for any irregularities on the surface or deviations in size that may indicate the need for replacement. Additionally, ensuring that the balls are stored properly when not in use can prolong their lifespan. Utilize protective cases or trays that keep the balls organized and shielded from potential impacts. By adhering to these maintenance practices, you can maximize the performance and accuracy of precision balls in your projects, ultimately leading to better results.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.