Stainless steel ball bearings are crucial in various machinery applications. They reduce friction, enabling smoother operation and longer service life. John Smith, a renowned expert in the industry, stated, "Stainless steel ball bearings are the backbone of efficient machinery." This highlights their fundamental role in engineering.

These components are composed of tough stainless steel, giving them superior corrosion resistance. They work by allowing rotation between moving parts, which minimizes wear and tear. In practice, they are found in everything from skateboards to large industrial machines.

However, not all stainless steel ball bearings are created equal. The choice of material and design can impact performance. Users often overlook the importance of precision and quality. A small flaw can lead to failure. While their advantages are clear, it’s essential to approach their selection and maintenance with care.

Stainless steel ball bearings are essential components in many machines. They reduce friction between moving parts. These bearings are made of high-quality stainless steel, which is resistant to rust and corrosion. This quality makes them ideal for various applications, from bicycles to industrial machinery.

Ball bearings consist of small steel balls nestled between inner and outer rings. The balls allow smooth rotation. They help distribute weight evenly. However, one common issue is misalignment of the components during installation. If they are not properly aligned, performance can suffer. Regular maintenance is also critical; without it, bearings may wear out faster.

Despite their benefits, there is room for improvement. Manufacturers must continually refine these products. Some users may find them too noisy or inefficient under certain conditions. Exploring different materials and designs could enhance their longevity and performance further. Understanding these factors ensures better usage and maintenance of stainless steel ball bearings.

Stainless steel ball bearings are essential components in many machines. Their durability and resistance to corrosion make them a popular choice. The composition of stainless steel varies, which influences the performance of the ball bearings. Typical elements include chromium, nickel, and molybdenum. Chromium provides corrosion resistance, while nickel adds ductility. Molybdenum enhances strength at high temperatures.

There are several types of stainless steel commonly used. Type 304 is popular due to its excellent resistance to oxidation and high strength. Type 316 offers even better corrosion resistance, especially in marine environments. However, it can be more expensive. Type 440 is a high-carbon stainless steel known for its hardness. Each type has its own unique properties, which can lead to confusion when selecting the right one.

While stainless steel ball bearings excel in many areas, they are not perfect. Their performance can decline under extreme conditions. Factors like temperature and load can severely impact their lifespan. It's crucial to consider these elements when choosing bearings for specific applications. Mistakes in selection can lead to premature failure, causing significant issues in machinery.

Stainless steel ball bearings play a crucial role in various machines. These components help reduce friction between moving parts, allowing for smoother operation. The design includes a series of small balls encased in a ring. This setup minimizes contact surfaces, leading to efficient energy transfer.

In terms of functionality, stainless steel ball bearings operate through rotation. They enable parts to move seamlessly against one another. As one part rotates, the balls roll within the races, creating less resistance. This action helps prevent wear and tear on the surfaces. Regular maintenance is necessary to keep them in optimal condition. Without it, they can rust or wear out prematurely.

The effectiveness of stainless steel ball bearings depends on quality and precision. Small defects can lead to bigger problems over time, causing inefficiencies. It's essential to choose the right size and type for specific applications. Each machine has its own requirements, which must be considered. Ignoring these factors can result in unexpected failures.

| Property | Description |

|---|---|

| Material | Stainless Steel |

| Corrosion Resistance | High resistance to rust and corrosion |

| Load Capacity | Varies by size and design, typically high |

| Friction | Lower friction compared to other bearing types |

| Operating Temperature | Effective in a wide range of temperatures |

| Applications | Used in machinery, vehicles, household appliances |

| Maintenance | Requires occasional lubrication |

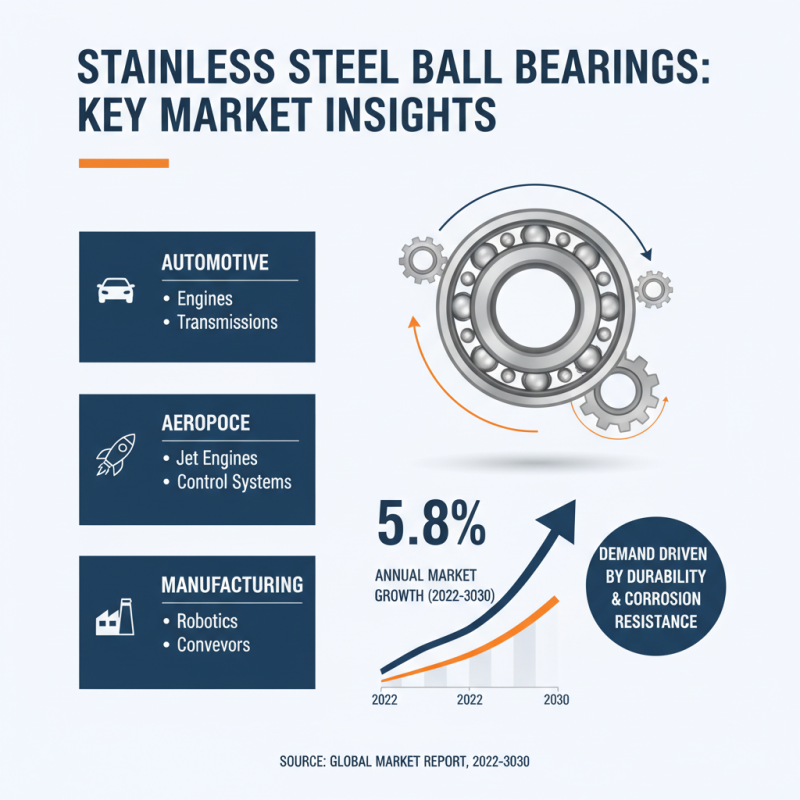

Stainless steel ball bearings are essential in various industries. Their durability and corrosion resistance make them ideal for challenging environments. They are commonly used in automotive, aerospace, and manufacturing sectors. According to a recent market report, the stainless steel ball bearing market is expected to grow by 5.8% annually from 2022 to 2030. This figure indicates a rising demand for reliable components.

In the automotive industry, these bearings support engines and wheel systems. They ensure smooth operation, contributing to vehicle performance and safety. The aerospace sector uses them in critical applications like landing gear and turbine engines. Reports suggest that nearly 30% of new aircraft designs integrate stainless steel ball bearings for their reliability.

Manufacturing equipment relies heavily on these components. They help reduce friction, leading to longer machinery life and reduced maintenance costs. However, not all applications benefit equally. Some industries face challenges, such as increased thermal expansion and contamination. Understanding these limitations is crucial. Proper selection can enhance performance, but common mistakes occur in design and implementation stages. Examining existing applications allows for continuous improvement.

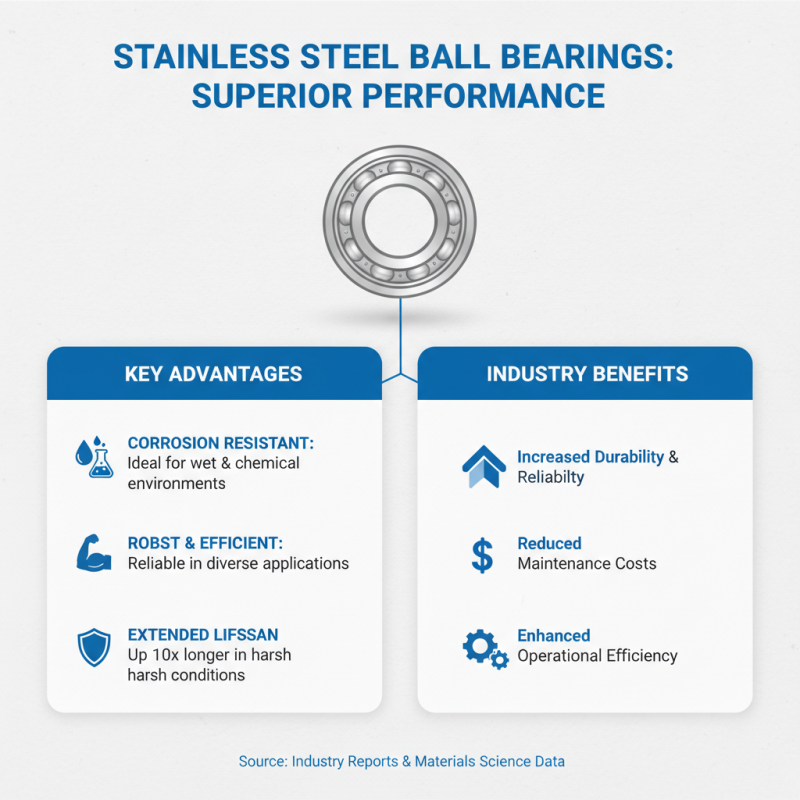

Stainless steel ball bearings are widely used in various applications due to their robustness and efficiency. One significant advantage is their resistance to corrosion. This attribute makes them ideal for environments exposed to moisture or chemicals. According to industry reports, stainless steel ball bearings can last up to 10 times longer than their carbon steel counterparts when exposed to harsh conditions.

Another notable benefit is their strength. Stainless steel bearings can withstand high loads and pressures. Their design allows for smooth operation, reducing friction and wear. In fact, studies have shown that using stainless steel can improve the lifespan of bearings by up to 50%. This efficiency translates into less downtime and maintenance costs for businesses.

Tips: Regularly inspect bearings for wear. Early detection can prevent larger issues. Ensure proper lubrication for optimum performance. Clean bearings periodically to avoid contamination. Remember, while stainless steel offers many benefits, it is not always the ideal choice for every application. Consider your specific needs when selecting materials.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.