Choosing the right tungsten ball bearings can make a significant difference in performance and durability. According to industry expert Dr. Edward Leung, “Tungsten ball bearings are unmatched in strength and precision.” This highlights the importance of informed selection.

Tungsten ball bearings offer various advantages over traditional materials. They are known for their high density, exceptional hardness, and resistance to wear. However, navigating through options can be overwhelming. The key is understanding your specific needs.

Many overlook crucial factors when selecting. It’s essential to consider bearing size, load capacity, and environmental conditions. This choice influences how well the bearings perform in applications. Even minor oversights can lead to failures down the road. Equip yourself with knowledge to avoid costly mistakes in your project.

Tungsten ball bearings are known for their durability and strength. They are made from tungsten carbide, giving them remarkable hardness. This material allows them to withstand high temperatures and heavy loads. Many industrial applications benefit from this toughness, especially in demanding environments.

One key feature is corrosion resistance. Tungsten ball bearings handle moisture and chemicals well. This makes them ideal for use in harsh conditions, such as automotive or aerospace settings. However, the initial cost can be higher compared to other materials. It's essential to assess the true value you gain from their durability.

These bearings also have a unique weight advantage. Tungsten is denser, so these bearings can reduce the overall weight in machinery. Lighter machinery can enhance performance and energy efficiency. Yet, some may overlook the maintenance requirements, which are vital for longevity. Regular checks can help prevent unforeseen issues, but many users often forget this step. This leads to wear and reduced functionality over time.

When evaluating tungsten ball bearings, assessing quality is crucial. Tungsten has unique properties that make it ideal for high-performance applications. According to a market report by Grand View Research, the global demand for tungsten components is expected to reach $8 billion by 2025. This indicates a growing recognition of tungsten's advantages, particularly its dense nature and resistance to wear.

The first factor to consider is the manufacturing process. Quality control during production can significantly affect performance. For instance, the uniformity in size and roundness can impact how well the bearings perform under load. A study from the American Society of Mechanical Engineers highlights that even minor deviations can lead to inefficiencies and increased friction.

Another aspect is the surface finish. A smooth surface enhances durability and reduces wear. Reports suggest that poor finishing can lead to premature failure. Take note of any visible imperfections; they could signal deeper issues. Ensure the bearings meet standard specifications, but remember that certificates alone do not guarantee performance. Always seek additional evidence of reliability through user experiences or industry benchmarks.

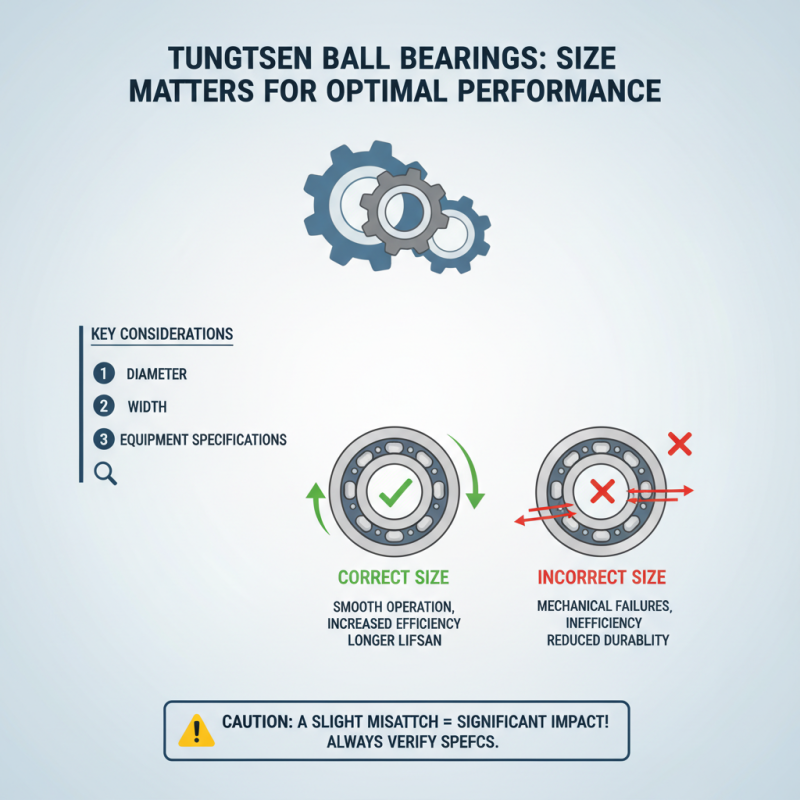

Choosing the right tungsten ball bearings is crucial for optimal performance. Size is a primary factor. Bearings come in various diameters and widths. Choosing the wrong size can lead to mechanical failures or inefficiencies. Always check the specifications of your equipment. A slight mismatch can create a significant impact.

Weight is another key consideration. Tungsten bearings are heavier than many alternatives. This weight can affect the balance and speed of your machinery. Make sure that the added weight aligns with your project needs. Test various weights to understand their influence on performance. It’s essential to find a balance that doesn’t compromise speed.

Compatibility with existing components is vital. Not all bearings fit every setup. Review the assembly instructions and design parameters. Some users overlook this detail, leading to compatibility issues. It's worth investing time in a thorough compatibility check. Ensure everything meshes well for seamless operation.

When selecting tungsten ball bearings, performance and cost are crucial. Tungsten ball bearings offer superior strength and durability. They can withstand high pressures and extreme temperatures. This resilience makes them ideal for heavy machinery, automotive applications, and aerospace components.

However, costs can be a concern. Tungsten is more expensive than other materials. Buyers must consider initial investment vs. long-term benefits. Cheaper alternatives may wear out faster and require frequent replacements. This could lead to higher overall costs. It's essential to evaluate the specific needs before making a decision.

Additionally, think about the application. High-performance tasks require premium bearings. But for light-duty use, mid-range options may suffice. Analyzing your actual needs can prevent overspending. Reflections on past choices can guide future purchases. Sometimes, it's better to invest in quality than to chase lower prices.

Tungsten ball bearings are durable and efficient, but they need proper care. Regular maintenance can significantly extend their lifespan. Start by keeping them clean. Dust and debris can accumulate and impede performance. A soft cloth can help remove particles without scratching the surface.

Lubrication is another key factor. Using the right lubricant decreases friction and prevents wear. However, be cautious. Too much lubricant can trap dirt, leading to issues. It's a fine balance that requires attention. Regularly check the bearings for signs of wear or damage. Even minor issues can grow worse if ignored.

Temperature changes can also impact performance. Tungsten bearings may behave differently in extreme temperatures. Monitor the operating environment and adjust as needed. Reflect on the specific needs of your application. Each setting is unique. Tailoring your maintenance routine is crucial for ensuring longevity and efficiency.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.