In today's fast-paced industrial landscape, enhancing mechanical efficiency is a critical pursuit for manufacturers seeking competitive advantage. One innovative solution gaining traction in various sectors is the integration of plastic bearings. Unlike traditional metal bearings, plastic bearings offer distinct advantages, including reduced weight, increased corrosion resistance, and enhanced durability under diverse operating conditions. This article explores the multifaceted benefits of plastic bearings and their role in streamlining mechanical systems. By delving into recent insights and innovations in bearing technology, we aim to provide a comprehensive guide that not only highlights the practical applications of plastic bearings but also offers strategies for successful implementation.

As industries continue to evolve, understanding how to leverage these advanced components can lead to significant gains in performance, efficiency, and overall cost-effectiveness, positioning organizations for sustained success.

Mechanical efficiency is a crucial factor in engineering applications, impacting the overall performance and sustainability of machinery. By maximizing mechanical efficiency, engineers can reduce energy consumption, minimize wear and tear on components, and enhance operational reliability. Understanding the principles of friction, load distribution, and component design is essential to achieving optimal mechanical performance.

Mechanical efficiency is a crucial factor in engineering applications, impacting the overall performance and sustainability of machinery. By maximizing mechanical efficiency, engineers can reduce energy consumption, minimize wear and tear on components, and enhance operational reliability. Understanding the principles of friction, load distribution, and component design is essential to achieving optimal mechanical performance.

One innovative solution for improving mechanical efficiency is the use of plastic bearings.

These lightweight alternatives to traditional metal bearings offer reduced friction and increased corrosion resistance. They excel in applications where lubrication is challenging, providing a more consistent performance and lower maintenance requirements. Engineers should consider incorporating plastic bearings in areas subject to high speeds or severe environmental conditions to leverage their benefits fully.

Tips:

When selecting plastic bearings, evaluate the specific application conditions, such as temperature and load capacity. Additionally, consider the type of plastic material that best fits the operational environment. Regularly monitor the performance of plastic bearings to identify any changes or signs of wear, which can help maintain mechanical efficiency over time.

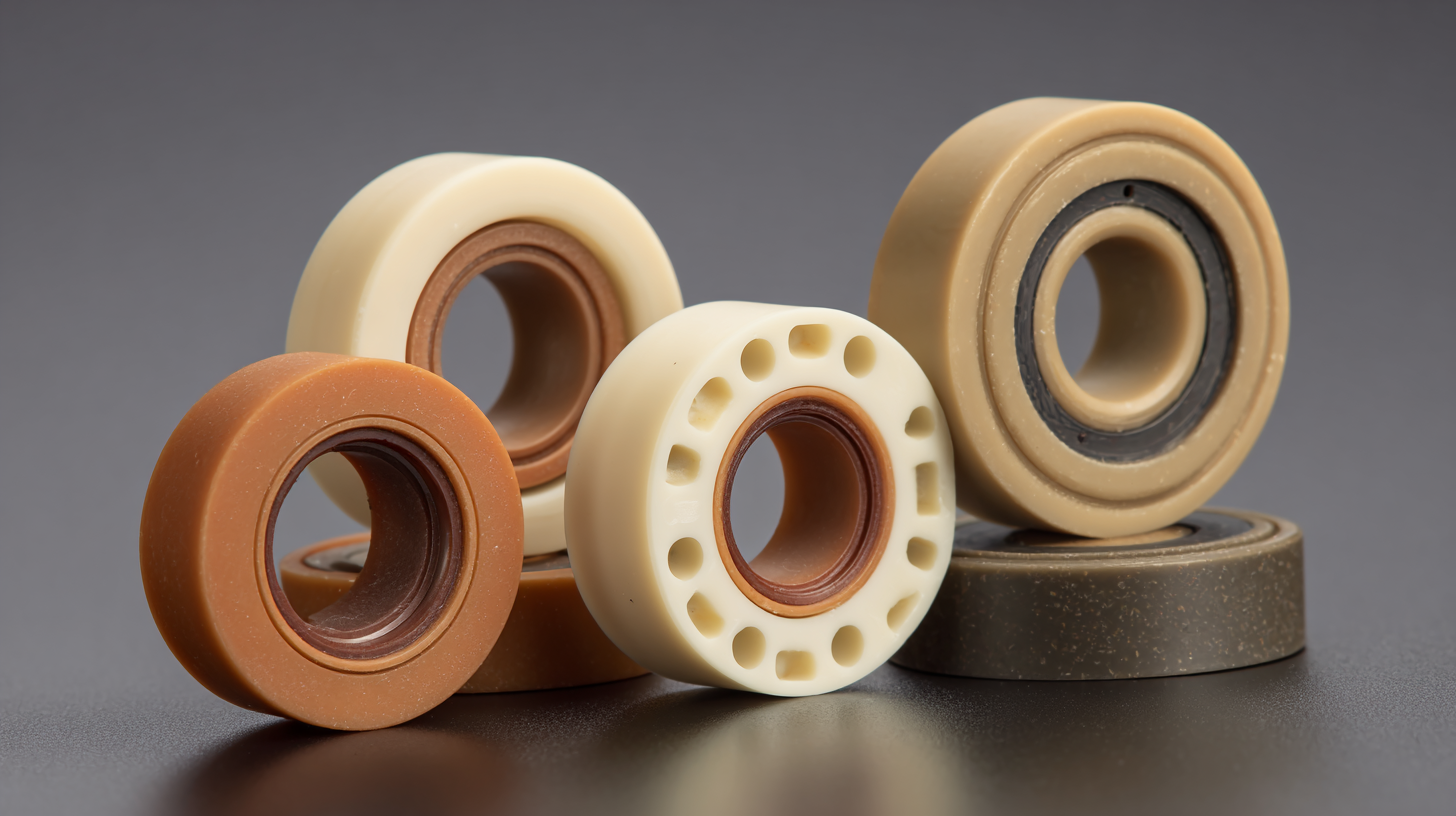

Plastic bearings are increasingly recognized for their numerous advantages over traditional metal bearings, especially in applications where weight reduction and corrosion resistance are critical. According to a report by the International Journal of Advanced Manufacturing Technology, plastic bearings can be up to 80% lighter than their metal counterparts, which significantly enhances the mechanical efficiency of equipment, especially in industries like

automotive and aerospace. The reduced weight not only decreases energy consumption but also improves overall system responsiveness and agility.

Moreover, plastic bearings exhibit exceptional resistance to corrosion and wear, making them ideal for environments exposed to harsh chemicals or moisture. A study published in the Journal of Materials Science found that plastic bearings can endure continuous operation in aggressive conditions with minimal degradation. Additionally, they offer a lower coefficient of friction, which can lead to improved performance and reduced energy loss in moving parts. In fact, manufacturers have reported up to a 20% increase in operational lifespan when utilizing plastic bearings, demonstrating their potential to enhance mechanical efficiency while lowering maintenance costs over time.

Incredible innovations in plastic bearings have paved the way for significant advancements in mechanical efficiency across various industries. One key innovation is the integration of advanced polymer materials, which not only reduce friction but also improve wear resistance. These materials can withstand a wide range of temperatures and environmental conditions, making them ideal for applications in automotive, aerospace, and machinery. The use of specialized lubricating additives within the plastic matrix further enhances performance, allowing for smoother operation and extended service life.

Another notable design trend is the incorporation of smart technology into plastic bearings. By embedding sensors that monitor operational parameters such as temperature, load, and speed, manufacturers can gain real-time insights into bearing performance. This data-driven approach enables proactive maintenance and reduces the risk of unexpected failures. Additionally, optimized geometric designs, such as unique shapes and sizes tailored to specific applications, contribute to better load distribution and greater overall efficiency. These innovations not only enhance performance but also contribute to sustainability efforts by minimizing the environmental impact associated with traditional metal bearings.

The integration of plastic bearings into mechanical systems offers a range of advantages, particularly in enhancing mechanical efficiency. Recent trends highlight how these materials can outperform traditional metal bearings in various applications due to their lightweight nature and reduced friction. According to a study by the International Journal of Engineering Research, plastic bearings can reduce weight by up to 50% compared to their metal counterparts, significantly improving energy efficiency in machines. Furthermore, innovations in polymer development have led to materials that are not only durable but also capable of operating in harsher environmental conditions, providing a compelling case for their adoption in sectors such as automotive and aerospace.

Implementing best practices for plastic bearings involves understanding their specific properties and the conditions they will face in use. As per recent reports in the Journal of Sustainable Materials, utilizing advanced production technologies can enhance the mechanical performance of plastic bearings by improving their load-bearing capabilities and wear resistance. Additionally, regular monitoring and fault diagnosis practices should be integrated into maintenance plans to identify potential failures early, particularly in high-stress environments. Leveraging these insights can lead to more reliable operations and decreased downtime, ultimately driving improvements in overall mechanical performance and sustainability.

In various industries, the integration of plastic bearings has demonstrated significant advantages over traditional metal bearings. One exemplary case is in the automotive sector, where a leading manufacturer adopted plastic bearings in their engine assembly. The lightweight nature of these bearings not only reduced overall vehicle weight but also minimized friction, leading to enhanced fuel efficiency. The move resulted in a decrease in manufacturing costs and improved performance, ultimately providing a competitive edge in a crowded market.

Another compelling example can be found in the food processing industry. A prominent packaging company replaced its metal bearings with custom-engineered plastic alternatives. This shift was motivated by the need for better corrosion resistance in moist environments, which metal bearings could not provide effectively. The plastic bearings ensured a longer service life, reduced maintenance downtime, and maintained hygiene standards without compromising operational efficiency. These case studies illustrate how innovative solutions in plastic bearing technology can lead to improved mechanical efficiency and significant operational benefits across diverse applications.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.