Choosing the right stainless steel ball bearings is crucial for ensuring the efficiency and longevity of mechanical systems. According to industry expert Dr. Emily Johnson, a leading researcher in bearing technology, "Selecting the appropriate stainless steel ball bearings can significantly enhance both performance and durability in various applications." This highlights the importance of understanding the different types of stainless steel ball bearings available, as well as the specific needs of your project.

In the world of engineering and manufacturing, the choice of bearings can impact not only functionality but also cost-effectiveness. Stainless steel ball bearings are renowned for their resistance to corrosion, which makes them ideal for use in challenging environments. As projects vary in their requirements—ranging from automotive applications to industrial machinery—being informed about the properties and performance characteristics of stainless steel ball bearings is essential for making the best selection.

Ultimately, the right choice can lead to smoother operations and reduced maintenance costs. This guide aims to provide insights and considerations to help you navigate the selection process effectively, ensuring that your project benefits from the best possible components.

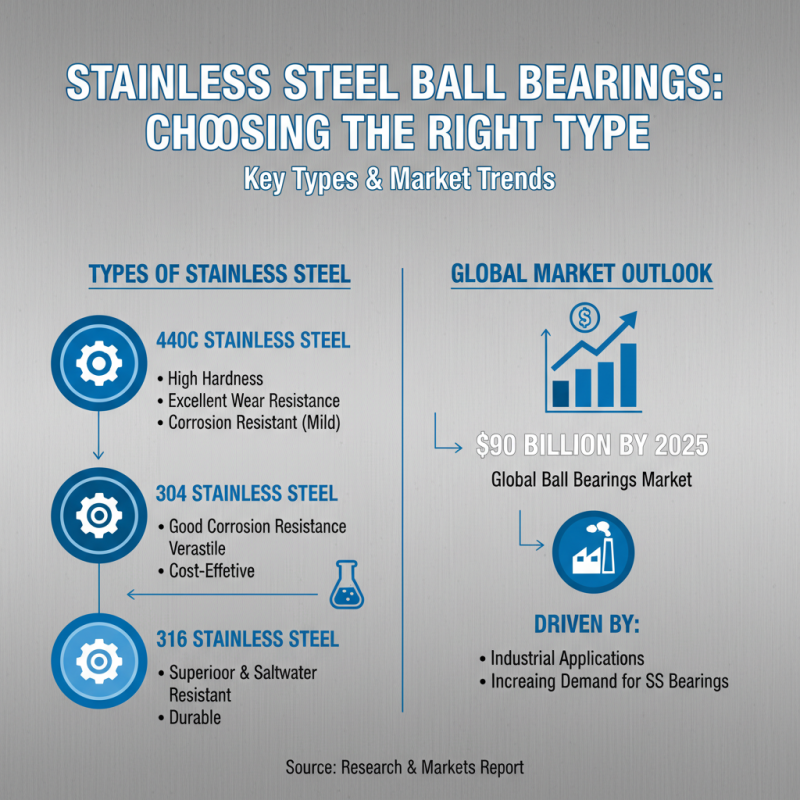

When choosing the best stainless steel ball bearings for your project, it is essential to understand the different types available and their unique properties. Stainless steel ball bearings are primarily categorized into three types: 440C, 304, and 316 stainless steel. According to a report by Research and Markets, the global ball bearings market is expected to reach $90 billion by 2025, largely driven by the demand for stainless steel bearings in various industrial applications.

440C stainless steel ball bearings are prized for their high hardness and wear resistance, making them a perfect fit for applications requiring durability in high-load environments. On the other hand, 304 stainless steel offers excellent corrosion resistance, suitable for applications in mildly corrosive environments such as food and beverage processing. Meanwhile, 316 stainless steel provides enhanced resistance to corrosion in saltwater and marine environments, making it the preferred choice in offshore and chemical processing industries. An industry study highlights that over 25% of stainless steel ball bearings are used in the automotive and aerospace sectors, emphasizing the critical nature of material selection based on specific project needs.

Understanding these distinctions will allow engineers and project managers to make informed decisions, ensuring optimal performance and longevity of the ball bearings in their applications. As industries continue to evolve, the importance of selecting the right stainless steel ball bearing type cannot be underestimated; doing so can significantly affect the efficiency and reliability of machinery.

When selecting the best stainless steel ball bearings for your project, several key factors come into play. First and foremost, consider the load capacity of the ball bearings. This is crucial as it will determine how much weight the bearings can support and how they will perform under varying loads. Understanding the dynamic and static load ratings will help you assess whether a particular bearing can handle your project’s demands.

Additionally, think about the size and design of the bearings. Ensure that they fit well within the space constraints of your application and that their dimensions align with the requirements for friction and motion.

Another important factor is the environment in which the ball bearings will operate. Stainless steel is an excellent choice for corrosive environments, but the specific grade of stainless steel used can significantly affect durability. You should also consider factors such as temperature fluctuations and exposure to moisture or chemicals, as these can impact the performance and lifespan of the bearings. Lastly, think about the lubrication requirements. Proper lubrication can reduce friction and wear, extending the long-term functionality of the bearings, so evaluate whether the bearings will be pre-lubricated or if you will need to maintain them regularly.

When selecting stainless steel ball bearings for a specific project, assessing the load capacity and durability is crucial. Load capacity refers to the maximum weight the bearing can support while maintaining efficiency and performance. According to the American Bearing Manufacturers Association (ABMA), the dynamic load rating (C) is a key metric, typically measured in newtons (N). For instance, a bearing with a dynamic load rating of 10,000 N can handle significant operational stress without failure, making it suitable for high-load applications such as industrial machinery or automotive components.

Durability, on the other hand, is an indicator of how long the ball bearings can last under regular use. Factors impacting durability include material properties, lubrication, and operating conditions. A report by the International Organization for Standardization (ISO) reveals that stainless steel bearings can often withstand high levels of corrosion and wear, significantly extending their life cycle in challenging environments. Specifically, AISI 440C stainless steel is recognized for its high hardness and wear resistance, making it ideal for applications subjected to heavy loads and adverse conditions. The choice of the right bearing, therefore, requires careful consideration of both load capacity and durability to ensure optimal performance in the long run.

When selecting stainless steel ball bearings for your project, evaluating size, tolerance, and maintenance needs is crucial to ensure optimal performance. Size is a fundamental consideration, as it directly relates to the machinery or application in which the bearings will be deployed. Precision in size affects not only the fit and function but also the load-bearing capabilities. Therefore, understanding the dimensions required for your specific application will help you avoid issues such as excessive wear or insufficient load capacity.

Tolerance is another significant factor that impacts the performance and longevity of ball bearings. Tolerance refers to the allowable variations in size and is critical for applications requiring high precision. Bearings with tighter tolerances can lead to smoother operation and reduced friction, which is essential in high-speed or high-performance applications. Conversely, if your project allows for more flexibility in terms of tolerances, you may opt for more cost-effective options while still achieving satisfactory performance.

Finally, understanding the maintenance needs of the bearings is essential for long-term reliability. Stainless steel bearings are generally resistant to corrosion, which is advantageous in harsh environments. However, they still require periodic inspection and lubrication to ensure they operate efficiently. Evaluating the maintenance requirements will help you determine the best type of bearing that aligns with your project's operational capabilities and maintenance resources, ensuring sustained performance throughout its lifespan.

| Bearing Size (mm) | Load Capacity (N) | Tolerance (mm) | Grade | Maintenance Frequency |

|---|---|---|---|---|

| 8 x 22 x 7 | 600 | ±0.01 | ABEC 1 | Every 6 months |

| 10 x 30 x 9 | 1200 | ±0.02 | ABEC 3 | Every 3 months |

| 12 x 32 x 10 | 1500 | ±0.02 | ABEC 5 | Every 6 months |

| 15 x 35 x 11 | 2000 | ±0.03 | ABEC 7 | Every year |

| 17 x 40 x 12 | 2500 | ±0.03 | ABEC 9 | Every 6 months |

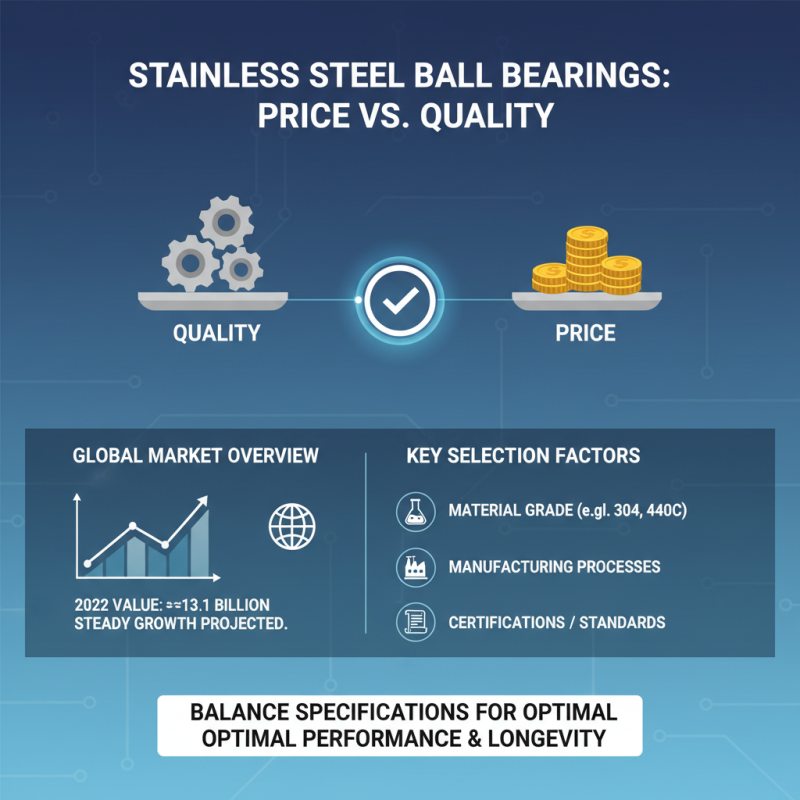

When selecting stainless steel ball bearings for a project, understanding the balance between price and quality is crucial. According to a recent industry report by Research and Markets, the global ball bearings market was valued at approximately $13.1 billion in 2022 and is projected to grow steadily. This growth indicates a competitive landscape where manufacturers strive to offer high-quality products while keeping prices in check. Buyers need to analyze specifications such as material grade, manufacturing processes, and certifications, as these factors significantly impact performance and longevity.

Quality assurance is not solely based on cost; it also involves evaluating the supplier's reputation and technological capabilities. A survey conducted by Grand View Research reveals that 67% of professionals in manufacturing prioritize quality over price when sourcing components. This trend underscores the importance of investing in reliable bearings that can sustain operational efficiency and reduce maintenance costs over time. In this context, a thorough comparison of different manufacturers, including assessments of their product durability, load ratings, and customer service, will help in making an informed decision that aligns with both budgetary constraints and project expectations.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.