Choosing the right stainless steel ball bearings is crucial for ensuring optimal performance and longevity in various applications. These small yet essential components play a pivotal role in reducing friction and wear, enhancing the efficiency of machinery ranging from simple household appliances to complex industrial equipment. Stainless steel ball bearings are particularly valued for their resistance to corrosion and rust, making them ideal for both indoor and outdoor use.

When selecting stainless steel ball bearings, it is important to consider several key factors. The specific requirements of your application, including load capacity, speed, and environmental conditions, will significantly influence the type of bearing that best suits your needs. Furthermore, understanding the different grades of stainless steel and their respective properties, such as hardness and resistance to specific chemicals, can help you make a more informed decision. This guide aims to provide insight into the essential considerations for choosing stainless steel ball bearings, ensuring you select the most appropriate option for your intended use while maximizing performance and durability.

Stainless steel ball bearings are essential components in a variety of applications, offering exceptional durability and resistance to corrosion. These bearings are constructed from high-quality stainless steel, known for its strength and longevity, making them ideal for environments where moisture and contaminants are prevalent. Understanding the different types of stainless steel used—such as 304 and 316 grades—allows users to select the most suitable option for their specific needs. Grade 304 is versatile and widely used, while 316 offers enhanced resistance to corrosive substances, making it better suited for marine or chemical applications.

When selecting stainless steel ball bearings, it’s important to consider several key factors including load capacity, speed ratings, and operational environment. Load capacity refers to the maximum weight the bearing can support without failing, which is critical for applications involving heavy machinery. Speed ratings indicate the maximum operational speed the bearing can handle, and exceeding this limit may lead to premature wear or failure. Additionally, understanding the operating conditions—temperature ranges, exposure to chemicals, and potential contaminants—will help ensure optimal performance and longevity of the bearings in their intended applications. By carefully evaluating these aspects, users can make informed decisions to effectively meet their bearing requirements.

When choosing the right stainless steel ball bearings for your application, it's crucial to identify several key factors that will influence your decision. First, consider the operating environment. High-temperature or corrosive environments require bearings that can withstand extreme conditions without compromising performance. Additionally, if your application involves exposure to moisture or chemicals, opt for bearings with superior rust resistance and durability.

Another critical aspect is the load capacity required for your application. Different designs and sizes of ball bearings provide varying load ratings. Be sure to assess the static and dynamic load requirements; this will help you select a bearing that can safely handle the forces it will encounter during operation.

**Tips:** Always refer to the manufacturer's specifications to ensure you're selecting a bearing that matches your load requirements. Additionally, consider the speed ratings, as some bearings are designed for high-speed applications while others are meant for lower speeds. Understanding these factors will enable you to make a more informed choice that enhances longevity and efficiency in your project.

When selecting stainless steel ball bearings, understanding the grade of stainless steel is crucial for ensuring optimal performance and longevity in various applications. The most commonly used grades for these bearings are 304 and 440C stainless steel. Grade 304 is a versatile choice, known for its excellent corrosion resistance and good mechanical properties, making it suitable for general purposes. However, for applications that require higher hardness and enhanced wear resistance, grade 440C is often preferred due to its higher carbon content and ability to be hardened through heat treatment.

According to industry reports, approximately 70% of stainless steel ball bearings utilized in harsh environments are made from grade 440C, as it can withstand extreme conditions without significant degradation. The choice between these grades will depend on the specific operational environment—while 304 stainless steel may suffice in less demanding scenarios, 440C’s properties are indispensable in applications involving elevated temperatures or exposure to aggressive chemicals. Furthermore, it is essential to consider integrated factors such as load capacities, lubrication needs, and maintenance during selection, as mismatched characteristics can lead to premature failure.

Ultimately, selecting the appropriate grade of stainless steel for ball bearings entails a careful analysis of all operational requirements. Investing in the right material not only enhances the efficiency of mechanical systems but also reduces long-term costs associated with maintenance and replacement. When in doubt, consulting with materials engineers and referencing industry-specific data can help in making informed choices tailored to specific needs.

| Grade | Corrosion Resistance | Thermal Stability | Load Capacity | Applications |

|---|---|---|---|---|

| 304 | Good | Moderate | Medium | General Purpose |

| 316 | Excellent | Moderate | Medium | Marine Applications |

| 440C | Good | High | High | High-Performance Applications |

| 420 | Moderate | Low | Low | Cost-Effective Solutions |

| AISI 316L | Excellent | High | Medium | Food Processing, Medical |

When selecting stainless steel ball bearings for specific applications, evaluating load capacity and performance specifications is crucial. Load capacity refers to the maximum load that a bearing can support without excessive deformation or failure. According to industry standards, angular contact ball bearings typically provide higher load capacities than deep groove ball bearings, making them preferable for applications that involve combined loads. For instance, a study from the Bearing Specialists Association indicates that the dynamic load ratings for high-quality stainless steel bearings can range from 1,000 to over 100,000 N, depending on the design and size, which highlights the importance of selecting the right type.

In addition to load capacity, performance specifications such as speed ratings and operating temperature ranges must also be taken into account. Based on data from the International Organization for Standardization (ISO), ball bearings used in high-speed applications should possess high-speed capability to prevent overheating and wear. The permissible operating temperature for stainless steel bearings is generally between -40°C to 120°C, but certain specialized designs can perform up to 200°C. Selecting bearings that align with both the load demands and the operational conditions can significantly extend the life of the bearing and improve overall equipment reliability.

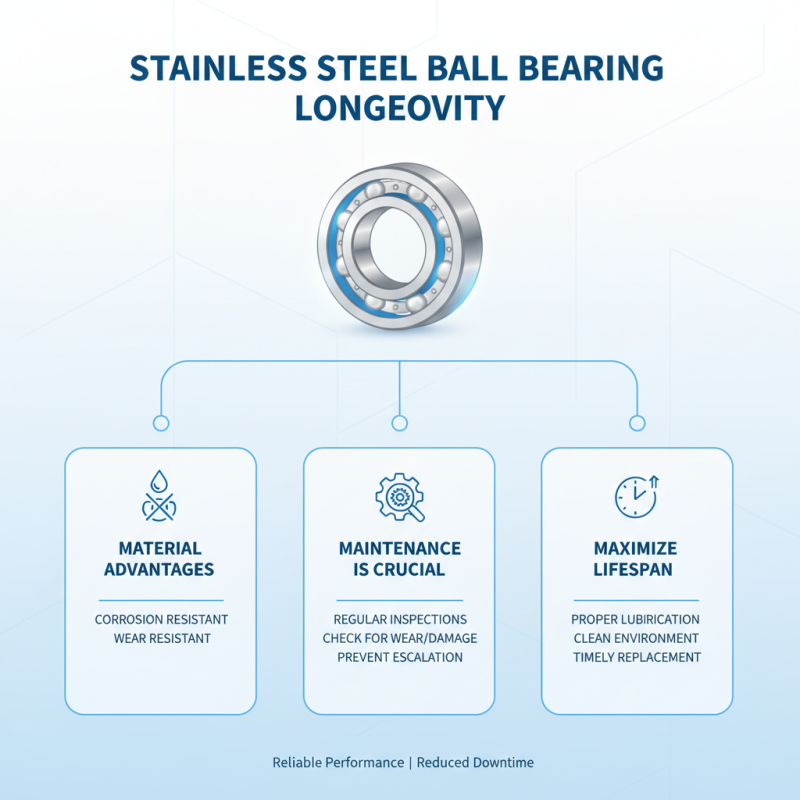

When selecting stainless steel ball bearings for a specific application, maintenance and lifespan considerations are paramount. The materials used in ball bearings, particularly in stainless steel variants, are designed to resist corrosion and wear. However, the longevity of these components heavily relies on regular maintenance practices. Routine inspections should be conducted to check for signs of wear or damage, as even minor issues can escalate and compromise bearing performance.

Proper lubrication is another critical factor in extending the lifespan of stainless steel ball bearings. Using the right lubricant ensures smooth operation and minimizes friction, which can lead to overheating and premature failure. Additionally, maintaining a clean environment around the bearings can prevent debris and contaminants from entering, which could hinder their functionality. By adhering to these maintenance practices, users can significantly enhance the endurance of their ball bearings, ensuring they perform optimally over time.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.