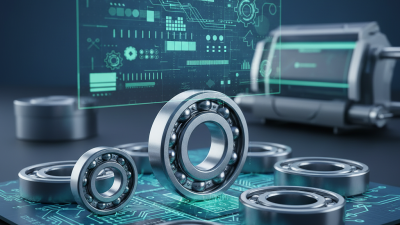

When embarking on a project that requires precision movement and reduced friction, selecting the right ball bearings is crucial. Ball bearings serve as fundamental components in various applications, offering support for rotating shafts and enabling smoother operation in machinery. However, with a myriad of options available on the market, understanding how to choose the appropriate ball bearings for your specific needs can be overwhelming.

To make an informed decision, it’s vital to consider multiple factors, including load capacity, bearing material, dimensions, and the environmental conditions in which they will operate. Each project may demand a unique set of specifications, making it essential to align your selection with the operational requirements of your machinery. This article aims to provide guidance on evaluating your project needs, ensuring that you select the most suitable ball bearings for optimal performance and longevity. By focusing on these criteria, you can enhance the efficiency and reliability of your project, ultimately leading to successful outcomes.

Ball bearings are essential components in various mechanical systems, reducing friction and facilitating smooth motion. Understanding the basics of ball bearings involves recognizing their primary types: deep groove ball bearings, angular contact ball bearings, self-aligning ball bearings, and thrust ball bearings. Each type is designed for specific applications and offers unique benefits. For instance, deep groove ball bearings are widely utilized due to their versatility and ability to accommodate both radial and axial loads, making them suitable for electric motors and automotive applications.

According to industry reports, the global ball bearing market is projected to exceed $25 billion by 2025, driven by advancements in technology and the growing demand for precision machinery. This increase necessitates choosing the right type of ball bearing based on load requirements, speed, and environmental conditions. For instance, if your application involves high-speed operations, angular contact ball bearings may be more appropriate due to their ability to handle axial loads effectively.

Tips: When selecting ball bearings, always consider the environment in which they will operate. Factors like temperature ranges, contamination, and lubrication availability can significantly impact bearing performance. Additionally, take into account the load type (radial vs. axial) to ensure optimal design compatibility. Conducting a thorough analysis of these parameters will help streamline decision-making and enhance the efficiency of your project.

When selecting the right ball bearings for your project, two critical factors to consider are load capacity and speed requirements. Load capacity refers to the maximum weight that a bearing can support without experiencing failure. It is essential to conduct a thorough analysis of the loads your application will impose. This often involves calculating static and dynamic loads, taking into account factors such as shock loads and operating conditions. Selecting a bearing with an appropriate load capacity will ensure stability and longevity in your systems, preventing premature wear or catastrophic failure.

Speed requirements are equally important, as they determine the operational efficiency of your application. Bearings are designed to function optimally within specific speed ranges, and exceeding these limits can lead to increased heat generation, noise, and eventual breakdown. When evaluating speed, also consider the type of motion in your project—whether it is continuous rotary motion or oscillatory. High-speed applications may necessitate special features like reduced friction or enhanced materials, which can enhance performance and reliability. Balancing these two critical factors will lead to more informed decisions during the bearing selection process, ultimately enhancing the overall effectiveness of your project.

When selecting ball bearings for a project, material choice plays a crucial role in determining performance and longevity. The most common materials used in ball bearings include steel, stainless steel, and plastic, each with distinct properties that cater to various applications. Steel ball bearings are often preferred for their strength and load-bearing capacity, making them ideal for high-load environments. However, they require proper lubrication and protection against corrosion.

On the other hand, stainless steel bearings are designed to resist corrosion and are suitable for applications exposed to moisture or harsh conditions. They offer a good balance between strength and corrosion resistance, making them versatile across different industries. Alternatively, plastic ball bearings, while generally not as strong as their metal counterparts, are lightweight and resistant to corrosion and chemical actions, which makes them a viable option for specialized applications where weight and resistance are critical factors.

When deciding on the material, factors such as the operating environment, load requirements, and the need for lubrication should be carefully considered. A thorough understanding of these variables will guide you in selecting the best ball bearing material that aligns with your project's specific needs, ensuring optimal performance and durability.

| Material Type | Load Capacity (N) | Speed Rating (rpm) | Temperature Range (°C) | Corrosion Resistance |

|---|---|---|---|---|

| Stainless Steel | 2500 | 5000 | -40 to 120 | High |

| Chrome Steel | 3200 | 6000 | -20 to 150 | Moderate |

| Ceramic | 1500 | 10000 | -50 to 200 | Very High |

| Plastic | 1000 | 3000 | -20 to 70 | Low |

Selecting the right ball bearings for your project requires careful consideration of several critical factors, particularly size, tolerance, and environmental conditions. Size is often the first consideration; it directly impacts the bearing's load capacity and performance. According to the American Bearing Manufacturers Association, using the optimal bearing size can improve efficiency by up to 20%. When determining size, project specifications and space constraints should be meticulously assessed to ensure that the chosen bearings will fit seamlessly within the design.

Tolerance is equally important when selecting ball bearings. The precision of the bearing's internal components, measured in microns, affects overall performance. Higher tolerances allow for smoother operation and reduced friction, which is vital in applications where speed and load capacity are paramount. Industry data indicates that even a small increase in tolerance could lead to a significant rise in operational efficiency, sometimes as much as 15%. Always consider the operational requirements of your project to determine the necessary tolerance levels for optimal performance.

When it comes to environmental conditions, factors such as temperature, humidity, and exposure to chemicals can greatly influence the longevity and reliability of ball bearings. Bearings exposed to harsh environments may require additional protective features, such as seals or coatings, to prevent corrosion and wear. For instance, a study from the International Journal of Precision Engineering reveals that bearings with specialized coatings exhibit a 30% longer service life in corrosive settings compared to standard options.

Tips: Always assess the specific operational environment before selecting bearings; extreme conditions necessitate more robust solutions. Prioritize understanding your project's load and speed requirements, as this can dictate both the size and tolerance necessary for optimal performance.

When choosing ball bearings for your project, understanding the balance between cost and performance is crucial. High-performance bearings often come with a hefty price tag, but they can lead to significant long-term savings by reducing maintenance costs and increasing the lifespan of machinery. It is essential to evaluate the specific requirements of your application, such as load capacity, speed, and environmental conditions, to determine whether investing in premium bearings is justified.

On the other hand, cost-effective bearings may be suitable for lower-demand applications where precision and durability are not as critical. Assessing the operational context can help identify situations where budget-friendly options are adequate. However, it is important to remember that opting for the cheapest alternative may result in higher expenses down the line due to potential failures or inefficiencies.

By carefully analyzing the trade-offs, you can make informed decisions that align both with your financial constraints and performance expectations.

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.