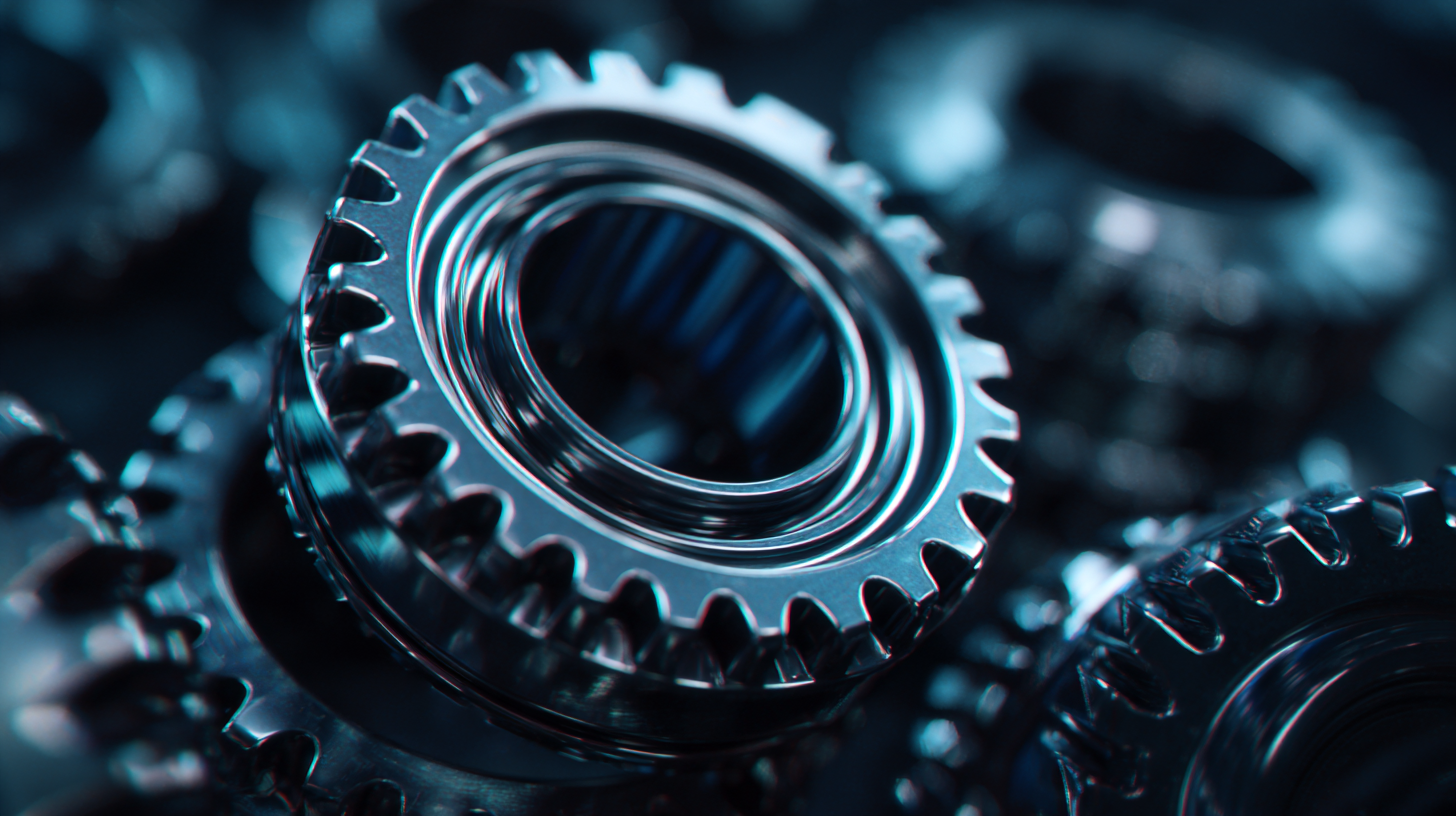

In the intricate tapestry of modern machinery, ball bearings play a pivotal role that often goes unnoticed. These small yet powerful components serve as the silent workhorses behind many everyday machines, from household appliances to industrial equipment. Their primary function is to reduce friction between moving parts, thereby enhancing efficiency and extending the lifespan of devices. The fascinating world of ball bearings encompasses a variety of types, each designed to meet specific applications and performance standards. From the precision engineering required in aerospace applications to the robust designs utilized in automotive technology, ball bearings are essential in ensuring smooth operation and reliability.

This exploration delves into the diverse types of ball bearings, their mechanisms, and the transformative impact they have on the machinery we rely on daily, shedding light on how these unsung heroes contribute to our modern lifestyle.

The historical evolution of ball bearings is a testament to human ingenuity and the quest for efficiency in machinery. Originating from simple wooden and metal constructions in ancient times, ball bearings have undergone significant technological advancements. The introduction of steel balls in the 19th century marked a pivotal moment, as it dramatically improved the durability and performance of these components. This evolution not only facilitated smoother operation of machines but also allowed for the development of high-speed machinery, transforming industries such as automotive, aerospace, and manufacturing.

Today, the industrial significance of ball bearings is more prominent than ever, with the global bearing market projected to surpass $100 billion by 2024. As industries seek to enhance productivity and minimize energy consumption, the demand for advanced ball bearing technologies continues to rise. In particular, the market for ball bearings is expected to grow significantly, with estimates indicating an increase from $7.26 billion in 2025 to $12.15 billion by 2032. This expansive growth reflects the critical role of ball bearings in improving mechanical reliability and performance, showcasing their vital contribution to modern engineering and manufacturing processes.

Ball bearings play a crucial role in minimizing friction and wear in various mechanical applications, which enhances the longevity and efficiency of everyday machines. Understanding the mechanics behind these components reveals how they effectively reduce energy losses and operational challenges. Recent advancements in tribological studies underscore the importance of surface characteristics and material properties. For instance, the development of multilayer Ti3C2Tx coatings has demonstrated exceptional wear-resistance under solid lubrication conditions, highlighting how tribo-chemically induced films can significantly enhance performance.

The thermomechanical characteristics of bearings, particularly in automotive applications, are also vital to optimizing their functionality. Double-row angular contact wheel bearings, for example, have shown improvements in thermodynamic performance, crucial for high-load scenarios. Research indicates that the correct surface texturing can further minimize friction in hydrodynamic journal bearings, indicating a growing interest in innovative designs that cater to specific loading conditions and lubrication regimes. These advancements in materials and designs reflect the continuous evolution in ball bearing technology and its profound impact on reducing wear and increasing machine efficiency across various industries.

Ball bearings play a crucial role in enhancing the efficiency and cost-effectiveness of everyday machines. By significantly reducing friction between moving parts, they enable smoother operation and minimize energy losses. This reduction in friction not only extends the lifespan of machinery but also decreases the need for frequent maintenance, resulting in significant cost savings for businesses. Industries ranging from automotive to aerospace benefit from the integration of ball bearings, which allow for more reliable and durable products.

The economic impact of ball bearings extends beyond mere cost savings; they also facilitate higher levels of productivity. In manufacturing environments, the enhanced efficiency achieved through ball bearing technology translates into faster production cycles and reduced downtime. Consequently, companies can meet consumer demands more effectively while maintaining a competitive edge in the market. The adoption of advanced ball bearing solutions further drives innovation, leading to the development of more sophisticated machinery that can perform at unprecedented levels.

Ball bearings are integral components that play a crucial role in modern technology and robotics. Their innovative design allows for smooth rotation and minimal friction, which is essential in applications ranging from household appliances to advanced robotics. In robotic systems, precision is key; ball bearings ensure that joints move fluidly and with accuracy, allowing for complex movements and enhanced performance. This level of efficiency is vital not only in manufacturing robots but also in assistive technologies that improve our daily lives.

Moreover, ball bearings are being explored in cutting-edge applications such as renewable energy technologies. Wind turbines, for instance, rely on large ball bearing systems to withstand the enormous forces of nature while maintaining their efficiency. Additionally, in the automotive industry, the integration of high-performance ball bearings in electric vehicles contributes to energy savings and extended battery life. The versatility of ball bearings is evident in their adaptability across various modern technological advancements, illustrating their importance in a world increasingly driven by automation and efficiency.

The future of ball bearings is poised for significant advancements, particularly in materials and design that emphasize sustainability. As industries become more eco-conscious, researchers are exploring alternative materials that reduce environmental impact while enhancing performance. Biodegradable composites and recycled metals are gaining traction, offering a viable path for reducing the carbon footprint associated with traditional bearing production. These materials not only contribute to a more sustainable manufacturing process but also help in meeting stricter regulatory requirements for environmental protection.

In addition to material innovation, the design of ball bearings is evolving to improve efficiency and lifespan. Advanced engineering techniques, such as computer modeling and 3D printing, are enabling the creation of bearings that are lighter, stronger, and more durable than ever before. These advancements not only enhance the performance of machines but also minimize energy consumption and waste throughout their lifecycle. As industries continue to prioritize sustainability, the development and integration of these advanced ball bearing technologies are set to play a crucial role in shaping a greener future for mechanical systems.

| Material | Benefits | Applications | Sustainability Features |

|---|---|---|---|

| Ceramic | Higher hardness, reduced friction | Automotive, Aerospace | Longer lifespan, lower energy consumption |

| Stainless Steel | Corrosion resistance, durability | Food processing, Marine applications | Recyclable, low maintenance |

| Plastic | Lightweight, cost-effective | Electronics, Household appliances | Made from recycled materials, energy efficient production |

| Hybrid | Best of both worlds (ceramic and metal) | High-performance machinery | Reduced wear, lower emissions |

To learn more about any of the products and services provided by Abbott Ball Company, Inc., simply complete the form below.